|

|||||||||||

Graphical Construction Glossary >> Woodworking

The range of woodworking is enormous. From the practical but also whimsical fancy of the 16Th century wood carver above to the huge manufacturing plants that turn out furniture, doors and moulding. Working with wood has spanned millennia. Australian Aborigines have been said to have used carved and painted message sticks for tens of thousands of years. Wood has been use for weapons and for ploughs. It has been used for shelter and it has been used n the form of boats and carts for transport and exploration. It is impossible to separate woodworking from the development of the world as we know it. The fact that wood is a natural material must have something to do with the actual sheer pleasure gained from working with it. The feel, the touch and the smell all come into it and the large and growing army of amateur woodworkers will attest to the satisfaction gained by getting involved in woodworking in one way or another. This is the introductory page in this glossary section in which I hope to steer you through the sometimes confusing terms in the English language that refer to working with wood. Many of these technical and specialised terms have made it into the language in general. We may say that something "goes against the grain", or talk about "a knotty problem" for instance.

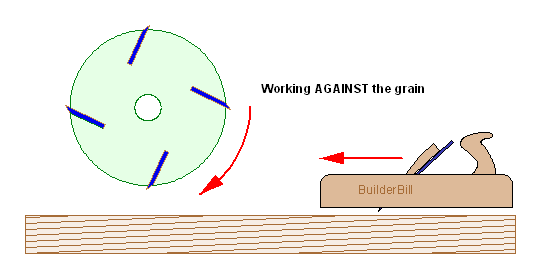

Timber made out of layers of growth that build up each year and this produces in all types of woods the main defining feature of wood. The grain. In ideal conditions we may be using a straight grained timber that has no blemishes and it has been sawn straight along the grain. This is the exception rather than the rule. In the sketch above a board is shown side on. If it is planed or machined in the direction shown then the result will be a rough or chipped surface. Working against the grain produces inferior results.

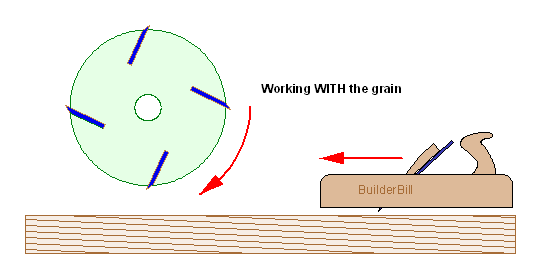

The first thing that any woodworker does before laying a tool or machine to a piece of wood is to look at it and observe the direction of the grain. There is always something to be gained by this and more often than not there is one particular slant of the grain that is the best. In the sketch above the tools would produce the best results going in the direction shown.

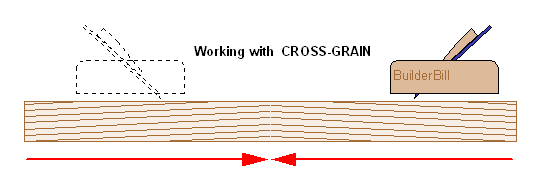

Coming as it does from trees and trees by nature have branches we often come across knots in timber which are the start of branches. Around knot the grain can go in different and opposite directions which if we are wanting to get a smooth finish can give us a knotty problem, One answer is to work from each direction separately. Another is to used a smaller tool with a more angled cutting surface suitable for working with contrary grain. In machine work it may be to sharpen up the blades and to take off less material with each cut. If you didn't find exactly what you are looking for try this search tool that will search the site and the web. "What can be added to the happiness of a man who is in health, out of debt, and has a clear conscience? "When we build, let us think that we build for ever."John Ruskin 1819-1900 |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Glossary Pages.Roof Glossary and Roofing Formwork Glossary and other tempory work. Hand Tools Glossary Power Tools Glossary Asbestos Glossary Woodwork Glossary Stair Glossary Concrete Glossary Masonry Glossary doors Glossary BuilderBill Books Building Maths  Stair Design  Asbestos Book |

||||||||||

|

|

|||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||||