|

|||||||||||||||

Graphical Construction Glossary >> Tools. >> Power Tools >> Wood Shaper

The old spindle above has the cutter mounted directly on top of the shaft. It is set up to scribe a quarter round on the shoulders of tenons. Spindle moulders have been around since the early days of the industrial revolution. They are NOT just larger router tables as some simpletons on the web seem to think. I served my time as an apprentice joiner in the late 1950's using an 1 1/4" spindle with a three speed belt drive. Later when I had my own workshop I very soon bought one for myself. At that time it was considered the most versatile machine in any woodworking shop. It was also considered the most dangerous machine.

The shaper is the supreme tool for finishing and moulding curved work. In just about all cases of straight work there are other machines that can do the job better. BUT and it is a big but, sometimes they are large and expensive and also you will need a few machines to get the versatility of a spindle moulder. Most spindle moulders are set up to cut sideways and most jobs use straight fences. Above is a large machine with a decent sized power feed.

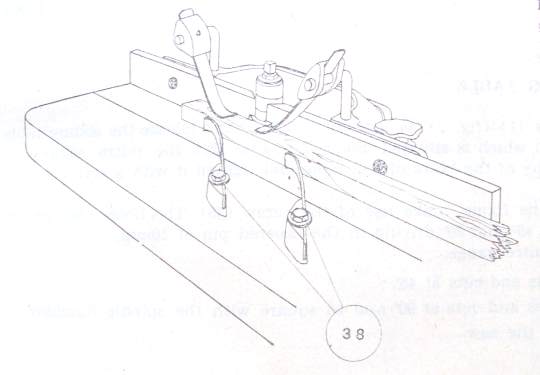

A sketch from the instruction manual for the above machine showing the layout of spring guides for the machine above. Part of the reason for the lack of popularity of the spindle moulder these days is the inherent danger associated the exposed cutter heads. Modern design improved safety greatly, but like all machine tools they should be treated with respect.

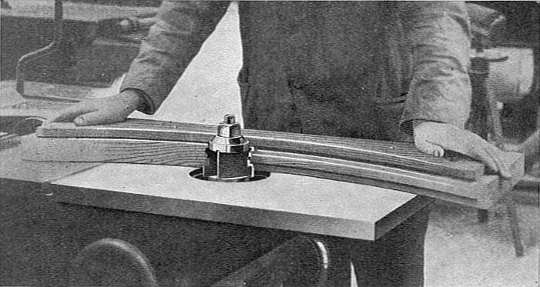

Above is a photo from an out of copyright book circa 1925. I am not to sure what the health and safety guys would think of this :-) Quite possibly some guides have been removed for the photo. No wonder spindle hands were known for missing fingers. Anyway it serves to illustrate some of the versatility of this machine.

This shot probably pre-dates heads with ball bearing top surfaces for guiding templates like this. The old spindle that I served my time on mostly just used standard straight fences and for curved work we had a ring fence or guide that sat just over the top of the head.

The head here has just two straight blades. It can be used for many tasks, smoothing curves or drop on work that is hard to do on a planer. It can make rebates, stopped or curved. Shapers have a rev range from 3,000 rpm to 10,000 rpm They do not need the huge revs per minute that routers do. It is all about rim speed or the speed of the cutting edge. For example a cutter block in a spindle may be 100mm diameter. A router bit at 33mm diameter will have to go three times faster to achieve the same cutting speed. But and here's the difference: the spindle tool may have more cutting surfaces and have more mass for smoother cutting.

Contrast the sleek modern machine above with it's safety guards in place to the photos above. As with many machines these days it is hard to pick their function from a simple shot like this. If you didn't find exactly what you are looking for try this search tool that will search the site and the web. "What can be added to the happiness of a man who is in health, out of debt, and has a clear conscience? "When we build, let us think that we build for ever."John Ruskin 1819-1900 |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Glossary Pages.Roof Glossary and Roofing Formwork Glossary and other tempory work. Hand Tools Glossary Power Tools Glossary Asbestos Glossary Woodwork Glossary Stair Glossary Concrete Glossary Masonry Glossary doors Glossary BuilderBill Books Building Maths  Stair Design  Asbestos Book |

||||||||||||||

|

|

|||||||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||||||||