|

|||||||||

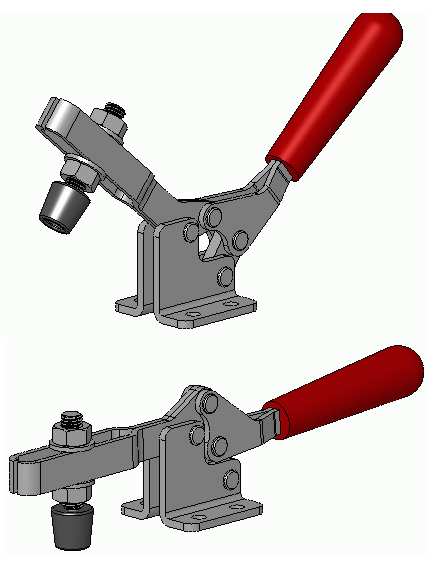

Graphical Construction Glossary >> Tools. >> Hand Tools >> Toggle Clamps

The word toggle mean something that is either on or off. Used as a switch. There is no in-between. So it is with these clamps. They should be set up with care so that just the right amount of pressure is used every time. When the clamp is pulled on then the mechanism locks itself. If it is only part of the way to being closed then it is not secure. When I gave up my day job (for about 9 months) a few years ago I made all of my own equipment for making hand made serigraphs or art screen prints. One of the the critical pieces of equipment was a vacuum table. I had to find a way of holding firmly in position quite large and heavy RHS screens. At the same time they had to be able to be easily and quickly changed. A pair of these small but powerful clamps was the answer. They worked perfectly. I thought at the time and I still do that they are excellent tools in a joinery shop for repetition work. They can be used in any number of applications where similar sized timber or jigs have to be held and worked on . There is quite a range of this type of clamping device available. They are very simple to set up and they can have many uses especially in the field of making jig for repetitious work

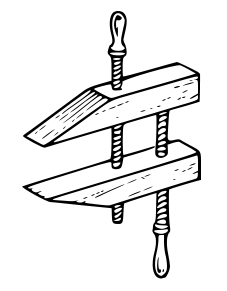

There is no way that these old wooden clamps can out-perform any of the new metal based clamps, yet many generations of carpenters and joiners have managed with a few of these clamps quite well. The secret of their use from biblical times is that they can be hand made and replaced and repaired by the same person that uses them. They have one ability that keeps a few of them around a joiner's shop. They can be clamped to a board and then themselves be held in a bench vise. This way the board (or whatever else) can be rotated or angled in many more ways than just in the vise alone. The ones that I can remember seeing and using had the handles with their threads made out of Boxwood, a dense and strong hardwood more known for it's use in chisel handles. The jaws were made out of Ash or a similar hardwood. The threads which were made on a wood turning lathe would have had a pitch of 4 to the inch. So why are the handles on opposite side? It has to do with opening and closing the jaws quickly. Imagine gripping a handle in each hand and making a motion similar to turning the pedals of a bicycle. The fast spin opens or closes them very quickly. If you didn't find exactly what you are looking for try this search tool that will search the site and the web. "What can be added to the happiness of a man who is in health, out of debt, and has a clear conscience? "When we build, let us think that we build for ever."John Ruskin 1819-1900 |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Glossary Pages.Roof Glossary and Roofing Formwork Glossary and other tempory work. Hand Tools Glossary Power Tools Glossary Asbestos Glossary Woodwork Glossary Stair Glossary Concrete Glossary Masonry Glossary doors Glossary BuilderBill Books Building Maths  Stair Design  Asbestos Book |

||||||||

|

|

|||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||