|

|||||||||||

Graphical Construction Glossary >> Doors. >> Door Hardware >> Mortise Lock

Above a typical quality mortice lock. From left to right is the strike plate, the body of the lock and the Forend. It has a standard backset of 60mm and the strike plate and forend are in satin finish stainless steel but there are other options available.

Supplied with what you see above and you get a split spindle and a solid spindle. Fixing screws and instruction sheet. This is fairly standard, in most types of quality mortice locks. The cylinder(s) and handles are ordered separately as there is a large range of them

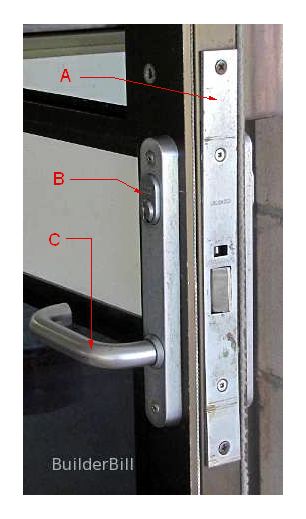

Regarding the door on the right:-

Modern aluminium framed doors are very hardware friendly. The extrusions are well designed to enable the fitting of hardware like locks and flush bolts. The fact that the sections are hollow makes mortice locks the favourite by far. The lock manufacturers in their turn produce lines of mortice locks that fit into various popular door sections. Narrow stiles like the one shown here mandate the use of lever handles and there is a huge range to choose from.

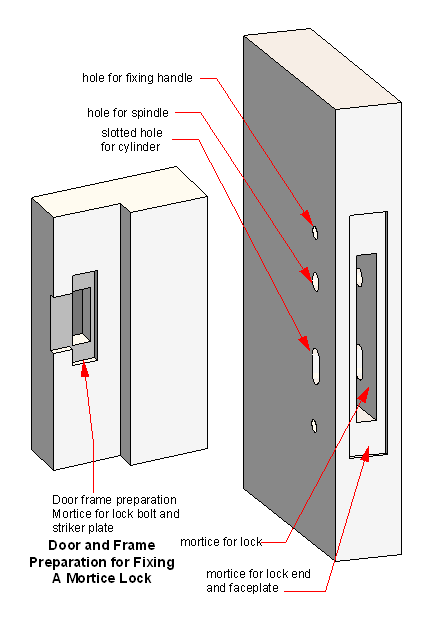

The sketch here shows the joiner's work in preparing the door and the the door frame ready for fixing the lock. Fixing locks like this requires a fair bit of skill and it is not a job that can be rushed. The measurements have to be very accurate as a small discrepancy can affect the good functioning of the lock. The lock manufactures supply various jigs for fixing these types of locks and anyone who has many of them to fix would find them a valuable investment. I have never used jigs for this sort of work, preferring to use electric drills and chisels. I must admit though that I have come perilously close to taking the drill point through the face of the door when drilling for the mortise. The trend is for thinner and cheaper doors and the thinner the door the more neat and accurate the mortice has to be as there is little tolerance. Chain morticer types of machines are available for taking out doing the main mortices and for the shallower ones for the plates a small router jig is ideal. The same router can also be used to do a lot of the main mortice and of course with a different jig it can be set up for recessing the hinges also.

Here is another lock that is a little more sophisticated than the previous one. As you can see it is deeper and incorporate a separate deadbolt and a non locking latch. The deadbolt protrusion is greater than the previous one. The photo shows two different forend finishes. If you didn't find exactly what you are looking for try this search tool that will search the site and the web. "What can be added to the happiness of a man who is in health, out of debt, and has a clear conscience? "When we build, let us think that we build for ever."John Ruskin 1819-1900 |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Glossary Pages.Roof Glossary and Roofing Formwork Glossary and other tempory work. Hand Tools Glossary Power Tools Glossary Asbestos Glossary Woodwork Glossary Stair Glossary Concrete Glossary Masonry Glossary doors Glossary BuilderBill Books Building Maths  Stair Design  Asbestos Book |

||||||||||

|

|

|||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||||