|

||||||

Graphical Construction Glossary >> Doors. >> Door types >> Flush Doors

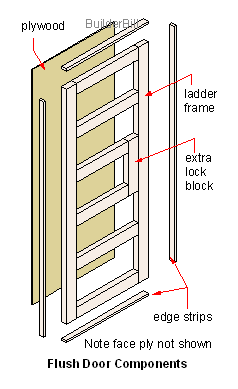

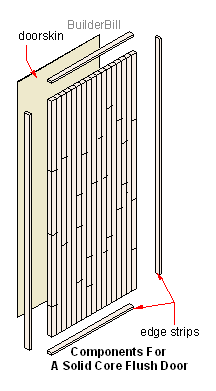

To the right is a sketch of a fairly good quality flush door. It is typical of well made doors of quite a few years ago. They had a decent timber frame and fairly thick ply faces. As with all the flush door types the strength of these timber and ply doors is in the glue that hold the sheets of ply to the frames. There are only butt joints in the frame members. These doors are not seen to often these days, the market has gone to the next two types. Typically they were made in thickness's of around 40mm. The Solid core door on the right is a lot stronger and heavier than the others and it seem to be the door of choice for external flush doors. The inner core consists of random lengths of fairly low grade softwood, knots included. Again the skin is nearly always a fairly good quality ply. They come in thickness of say 40mm to 45mm

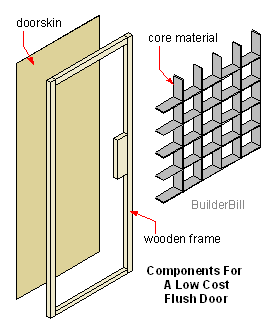

Above is a rough idea what a lot of cheap hollow core doors look like. Again I only show one sheet otherwise I would be covering up detail. The main thing here is that the perimeter timber is a lot smaller. It may be as narrow as 30mm. That is enough to fix hinges to OK, and an addition piece of timber is placed in the lock area. NOTE! As I said the door makers don't give anything away. The doors are always marked, "Hinge Stile", or "Lock stile". An all to often mistake is to forget about this and hang the door on the lock stile and then when it comes to fitting the handles there is nothing to screw to. Solid Core Door Blanks. These are simply large sized blanks of what can make a decent solid core door. They typically come in 2040mm high and 1200mm and 1000mm wide. So it is possible to buy one 1200 wide blank and make two 600 wide doors from it. Once the blank is cut then 12mm edge strips are glued on ALL the edges. Once again a trap for the unwary. I believe that doors blanks are great, I have used them for dozens of jobs, but at the same time I have seen many solid core doors that are disasters. What happens is that when using the doors blanks for external use many people just don't bother with the edge strips. The carpenter that fixes the door may or may not paint the top or bottom edges of the door, but the fact is that most times they don't get painted, so for the rest of the life of the door it is it is soaking in water into the end grains of those softwood core pieces. The result is in many cases disastrous. Doors being replaced in less than five years. If you didn't find exactly what you are looking for try this search tool that will search the site and the web. "What can be added to the happiness of a man who is in health, out of debt, and has a clear conscience? "When we build, let us think that we build for ever."John Ruskin 1819-1900 |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Glossary Pages.Roof Glossary and Roofing Formwork Glossary and other tempory work. Hand Tools Glossary Power Tools Glossary Asbestos Glossary Woodwork Glossary Stair Glossary Concrete Glossary Masonry Glossary doors Glossary BuilderBill Books Building Maths  Stair Design  Asbestos Book |

|||||

|

|

||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

||||||