|

||||||

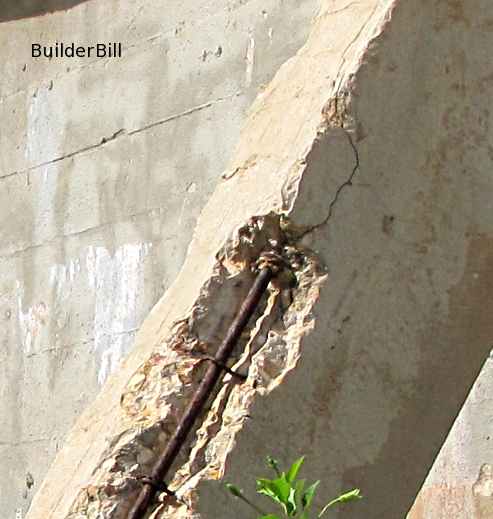

Epoxy concrete repairEpoxy concrete repair methods. A primer (no pun intended ;-) for repairing damaged concrete..

Regarding photo above. It would be a fairly brave man to take on a job of repairing this buttress. OK I have the benefit of seeing the surrounding structure and it does not look good. A typical repair specification may say something like "Cut back loose and damaged concrete to a solid base". What happens is that concrete like this when hit with a demolition breaker or jack hammer will start to show more cracks under the impacts and so it goes on. Many times jobs like this turn into a complete demolition and rebuild. Following on from the previous page I am offering here a few epoxy concrete repair methods that I have used on various jobs in the past. First some background:- I am not a structural engineer so what is contained on this Epoxy Concrete Repair page is in plain non-technical language that may give you a brief overview of this highly complex subject. I have worked with engineers extensively particularly on a few jobs where we had to repair structural defects in concrete. I won a contract quite a few years ago to repair a badly deteriorating concrete slab in the (salt-water) pump-house of our local power station. After completing that work I was asked to quote on quite a few other concrete repair jobs for our local Power and Water Authority. Mainly sewerage pumping stations (where there's muck there's money, lad :-) and the like that were suffering from the effects of long term chlorine use. It must be said that prevention is by far the best remedy. Make sure that your concrete is top quality with none of the defects listed on the previous page. Epoxy Resins (from the Greek epi = upon and oxy = sharp or acidic, and resin as in the substances exuded by trees etc.) were first discovered in the early 1900s, but they were pioneered for commercial use some time in the 1930s culminating in the company Ciba producing the first true epoxy resin in 1946. These chemical resins have uses in many and varied industries from aviation to super yachts. In the construction industry we use them for:-

Advantages of epoxy resins over other method of repairing concrete.

If defects in the concrete are noticed early on in the process then it may be possible to arrest further damage by simply applying a waterproof membrane. This will require preparing the surface and then applying primer, filling any depressions and holes with a putty like compound and then applying a protective coating. However in most cases that I have come across the damage has well and truly set in and a quick fix is out of the question. To a large extent this major damage will have been caused by lack of maintenance. You can be assured that ignoring these sorts of problems will not make them go away. Major repairs may consist of:- Remove affected concrete and replace with new concrete. Used on larger areas of damage.

Remove affected concrete and replace with an epoxy concrete.

Normal concrete uses aggregates water and cement. This epoxy concrete repair mixture consists of the epoxy resin/hardener and aggregates only. The advantages of this method is increased strength and bonding to the original. Also the ability to bond the new repair to the old where it may taper to a very thin edge.

There is a bewildering array of chemicals and waterproofing methods available and none of them are cheap. It is good advice to do as much research as you can before buying any of the high-tech construction chemicals. If you didn't find exactly what you are looking for try this search tool that will search the site and the web. |

Other Concreting Pages.

Joints in concrete flatwork |

|||||

|

|

||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

||||||