|

||||||||

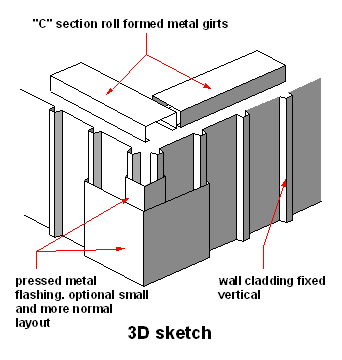

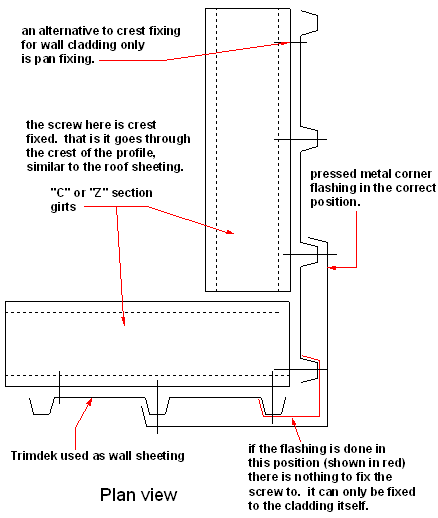

A wall flashing detail for a steel shed using Trimdek profile fixed vertically.A wall flshing question from a reader gets me to fire up my drafting program, as it is hard to answer questions like the one below from Phil in Palmerston, NT. with text alone. Looking for info on fixing colourbond flashings at building corners when Trimdek used running vertically. Flashing attached to Trimdek itself, not to girts etc. All info I get from people (including Certifier) is "fix as per manufacturers specifications". Can't find DTMC sheet covering it. Can it be pop riveted or does it have to be screwed. My answer to Phil was along these lines.

This makes for some big flashings at some corners and not at others,

which looks crap if you are using this system on say a house.

That being said, on most jobs this doesn't happen, the cladders just make bigger flashings and it is accepted, as the buildings are usually large industrial type sheds. If you have already fixed the sheeting, and bought the flashings, don't fix with pop rivets. They should not be used, (although the flashings for the Custom Orb at Parap Village is full of them). Fix to the sheet with normal looking screws, in line with the other screws, but try to get something extra behind to screw to. Phil gave me some more information.Bill, I gather that you are saying that the screws have to be on that flat area and not on the angled back section. Due to the fact that the Trimdek had to fastened to 4mm thick steel the screws for this have been 14-20x22mm hex heads with climaseal washers, but I've had to predrill each hole as even those screws are reluctant to easily get through the steel. These screws are rather large just for attaching the flashings to the underlying Trimdek so I'm hoping that I can use something a bit smaller like 10-16x16mm hex heads with washers so that they are less visible. So it seems that Phil's flashings look something like the small one in red in the sketch above.

Note! Building certifiers seem to have different ideas on things like this that are not documented or detailed. Some don't mind the use of pop rivets on these smaller flashings and others stick to the full size screws. So there are a couple of options.

Also Note! I show in the sketch above that the large flashing is going over two crests. This is mandatory on roof sheeting, but not of walls like this, the inner crest could quite easily be missing, but you must lap over one crest. Leave this wall flashing page and back to home. Not found it yet? Try this FAST SITE SEARCH or the whole web |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Some answered questions.

|

|||||||

|

|

||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

||||||||