|

||||||||||||||

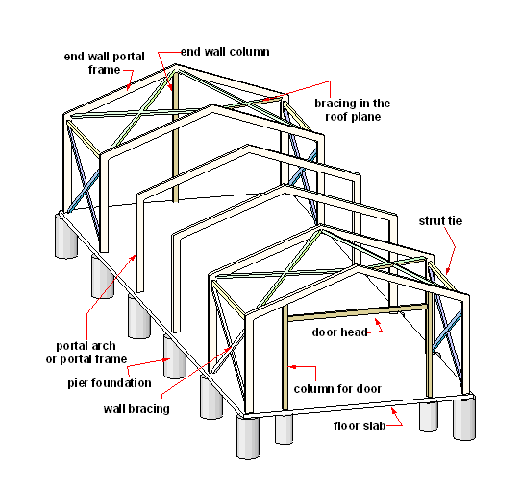

Steel shedsThis page about steel sheds is to give an intro into the materials used in all steel buildings and the common names of some of the members used. It will also lead on to other pages which go into more detail on specific items.

Portal Frame, portal arch or just portal.Portal frames are the basic item in all steel sheds of a certain size. You will see them, maybe just one in a small garden shed, or huge things weighing in at many tonnes in industrial buildings.

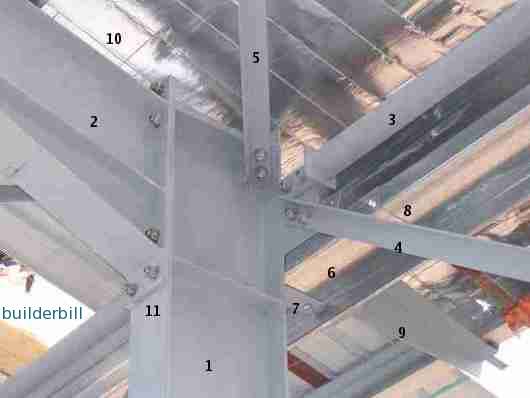

Apologies once again for the crap photo, but I have to keep the file size down for people with slower connections. if you could see this shot in high resolution, you would be able to see that all the bolts have a marking pen cross on them. What happens is the structural engineer will specify the amount that the structural bolts shall be tightened to. When the steelwork is erected, a guy goes around with a torque wrench and tightens them up to the correct setting, and then marks them off to show that it has been done. FootingsFooting are an integral part of the whole structure. What I have drawn here are cylindrical pier footings. In this case the footings are drilled by machine and filled with concrete, with hold down bolts set into the wet concrete. The main structural steelwork would then be erected, and the floor slab poured. With the slab poured than the rest of the building is finished with a good surface to work on. There are many different ways of providing support and hold down for steel work, so I will go into it in more depth. Check out the menu on the right. braces

Again there is a fair bit to be said about braces, you wouldn't believe how many different types there are, so I will go into them in more detail. Check out the menu on the right for updates to this section.

Looking at the sketch above you will see that the end walls have extra columns, to carry the wall girts and to frame around the door. This means because of the extra support then the end frames are not true portals, spanning the whole width, and as such they are carrying less load and many times can be made lighter. The photo above shows this, the end frames consist of single "C" purlins. while the main portal frames are made from double purlins. For this reason the designer has chosen to place the roof bracing between the true portals (the second bay from the end), that are carrying more load. Strut TiesStrut ties join/separate the portal frames at the top. As the name suggests they act as struts when under compression loads and as ties when under tension. On small residential jobs they are quite often site welded into position, and as the jobs get larger they use bolted connections.Steel purlins and girts

The purlin and girts are made out of the same standard cold rolled sections, usually 'C" or "Z" sections. The shapes are the same, the names change depending on whether they are on the roof or the walls. There are quite a few points to think about regarding purlins and girts, so once again I have done a separate page on these brilliant items. You would think that the humble bridging pieces would only take a paragraph to describe. Not so, you should know me by now. There are a few options, not the least is making your own, or doing without them entirely. Check out the menu on the right for my steel bridging page here. Leave this steel sheds page and back to home. Not found it yet? Try this FAST SITE SEARCH or the whole web |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Other Pages about the use of steel in residential consruction. |

|||||||||||||

|

|

||||||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

||||||||||||||