|

|||||||||||||||||||||||||||||||||||||||

Roof Truss Details

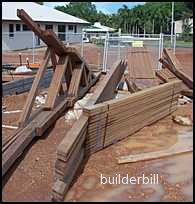

This page is about nail plated timber roof trusses. There are of course many other types of timber trusses in existence, but these are by far the most common used in residential construction today. These roof truss details are all of houses being built in a cyclone prone area and as such they have to be built to a strict building code. What with global warming and climate change, this type of construction may be coming to your area soon.

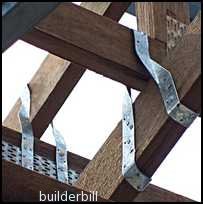

Some history.About the late 1950's early 60's prefabricated roof trusses came onto the scene. The name that still sticks with me is Gang-Nail. I may be wrong but I think they were the first company to build roof trusses that rely on a multi nail plate connector to mass produce cheap and easy roof trusses. There were quite a few methods of joining trusses around at the time, but most of them needed some drilling and bolting. The Gang-Nail plate is just a flat galvanised plate that has stamped in a press to produce dozens of pointed spikes on one of it's faces. One is placed on each side of a plain timber butt joint, and then a hydraulic press forces the plates together forming an extremely strong joint. They are no longer the cutting edge of roof design, rather they are used for the thousands of simple cost effective house designs that are mainstay of the house construction industry. They can not be used for flat pitch roofs. This type of roof construction is governed by strict Australian Standards. ( AS4440 at time of writing, but without a doubt it will change sooner rather than later:-) Advantages of lightweight trusses.

Some Disadvantages of metal nail plate Roof Trusses

General ConsiderationsI many cases the trusses are delivered to the site by a crane truck, which can lift them directly onto the walls. With every set of trusses you get a diagram and list of fixing instructions. Of particular interest to owner builders, there are small booklets available for free from the manufacturers, that show the various fixing details of all the components. Most of the roofs that I have done have used the "metal nail plate " roof truss system. They are an Australian company who have franchised outlets in major cities around Australia. metal nail plate do house trusses up to 45 deg. pitch and up to 16 m span. They are nearly always designed and built to span the external walls. On some of the details you may notice that some internal walls are connected to the roof truss framing. These are walls that the the structural engineer has designated a shear wall. That is wall that are designed to stiffen the main external walls. The fixing to the roof in these cases is just as much about holding the shear wall in position, as supporting the roof.

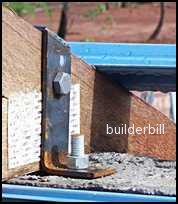

Here's a shot of a main roof truss on top of the walls. In this case the walls are series 200 (190 thick) hollow reinforced concrete blockwork. This type of wall is tremendously strong and stiff. Note the truss hold down bolts sticking out of the concrete, They are galv. M16 with a cog on the end, and are probably cast into the concrete corefill at least 200.

Here is a shot from underneath showing temporary timber props holding the roof trusses level. Also in this shot you can see that there are no masonry internal walls, instead the designer has chosen to use fully MIG weld steel wall frames, a few can be seen lying down on the left. Truss Layout Sketches

You may have noticed that unlike a traditional timber roof, when trusses are used, there is no ridge piece. it is not needed. The roofing battens hold the trusses securely on the top and the ceiling battens hold the bottom chords. The truncated girder truss is there to give extra strength to the hip areas. They are usually double the thickness of the ordinary trusses (two trusses of the same thickness nailed together), and often depending on the span and pitch of the roof there could be two of them at each hip end. Some truss details

A bit of a digression, I took these photos on one of my Saturday morning bicycle rides. It was a new subdivision with so far only a few jobs on the go. I pedaled into a site with an interesting steel roof, hoping to take some photos, but I was sprung by a young guy, obviously someone in authority,and he asked me to leave as I was on a construction site. He didn't say it but the implication was that It's dangerous for an old fart like me to be wandering around. Work health regulations and all that. I remarked to him with a grin, that at least I was wearing a helmet and boots, (a bike helmet:-) looking down at his bare feet. He didn't even have the grace to smile, just told me again to leave. Somebody once said that "youth is wasted on the young". I'll go along with that. Or at least on some of them.

Here is one of the almost finished houses. A Dutch gable over the double garage and hip ends elsewhere. Corrugated iron roof sheeting and two 300 whirlybird type ventilators. On the far side will also be a solar hot water system. Leave roof truss and back to roof basics Not found it yet? Try this FAST SITE SEARCH or the whole web |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Quick Illustrated Roofing Glossary Pages.Types of roofsRoof Features Roof Framing Roof Trusses Roof Coverings In Depth Roofing Articles

|

||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||||||||||||||||||||||||||||||||