|

|||||||||||||||||||

Door Frames or Door JambsI am not too sure on the terminology here. I always use the term "door jambs" but by far the most people I meet seem to call them door frames. It is probably more correct to refer to them as frames because the word jamb does indeed refer to only the upright pieces of a door or window frame. So wherever you see the term jamb take it as read that I am talking about the full frame on this page and other pages. Old habits die hard but I,m trying...

Modern steel frame door frames are great, they are stiff and resist bending. They already have the hinges on. They are compact to transport and can be easily assembled by semi skilled labour. A series of tabs in the jambs poke through slots in the head and are belted flat with a hammer. Spreaders at the bottom keep them at the correct size. You need to be on the ball with your selections though. When you go to the supplier to pick up the door jambs you need at least this minimum of information.

With stud walls usually it is a carpenter that fixes the door frames. It may or may not be the same guy that fixes the jambs and fixes the doors. Either way, you have a bit more time to get them right than the mad rush when a team of Prima Donna brickies descend on you.

In the above photo the plasterboard flusher has yet to sand. The metal stays at the bottom will be snipped off by the carpenter when he fixes the doors. A few examples of what can go wrong when bricking them in.

There is one that I missed in the sketch, that is for wider frames, say for double doors, you must provide support over the top, or in the case of reinforced blockwork, prop the frame to stop the head sagging while the blocks are being laid. In the sketch at the right, sighting from in to out through the opening, the left frame is perfect, but the other one is twisted. Most brickies do a good job, read the plans OK and fix the door frames and windows as they go. If you are an owner builder, keep an eye on them. If the door jambs are not true, the carpenter is going to squeal. Probably ask for more money. Correctly fixed jambs mean it is a breeze to fix the doors. Typical Layouts

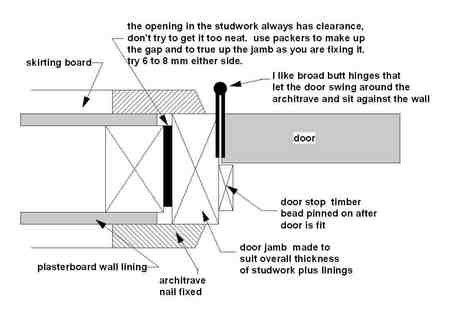

Above is a sketch of a timber door frame fixed to a timber stud wall. For a brick wall it would be similar, made by the carpenter on the job to suit the wall's finished thickness. Note the use of broad butt hinges that allow the door to open a full 180 degrees. With standard hinges the door would bind against the architrave.

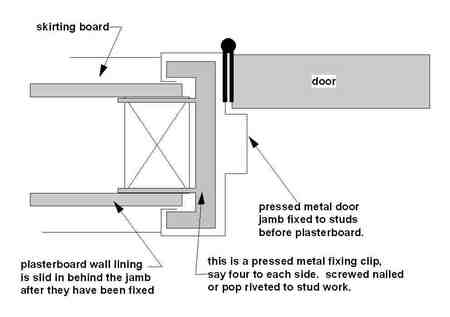

Here is a metal door frame in a stud wall. If it was in a brick wall the brickie would build it in as he builds the wall, using wire clips that get hooked into the frame and embedded in the mortar joints. About four to each side. Metal frames are simple to fix in stud walls, either steel of timber studwork. Just make sure you get the opening in the studwork right, as there are different allowances for the various types clips the manufacturers use. Fixing Timber Frames and Hanging DoorsHere's a question I have had from Tom (Australia). I am looking at installing some new external doors to a timber framed house. I was wondering whether it is better to pre assemble the door frame, pre hang the door in the pre assembled door frame and then install the whole unit at once. Or is it better to install sill and jambs separately to ensure plumb and hang door last. Hi Tom, The way that is normal is to make up your frame in one piece, with the sills and heads nailed or screwed up into the jambs. (I typically pre drill the holes and use 75mm bullet head nails for this, as they grip better in the end grain of the jamb than screws.) If the job is to be paint finished, paint inside of the joints as well before you put them together. Also paint under the sill if you can, it is never going to get any more paint in it's lifetime. The doors are usually fixed last, into the already fixed frames, mainly because the frames and outside cladding are fixed by a separate team. The second fix carpenter hangs the doors later. (usually whingeing about the frames being out of plumb etc). Don't fix down through the sill. These fixings make a potential spot for water to get in. Try to get a fixing from underneath, or if they are standard 820 doors, the fixing to the jambs should be enough with maybe a blob of liquid nails under the sill in the middle. I have fixed quite a few aluminium doors, which were obviously pre fitted by the manufacture, and they are always easy to fix, because you can see the various aspects of out level, twist, bow in the jambs etc. So you could do it the pre fitting way if you have a bench to work on Tom. This could be the best way to go for a first timer. I'd say pre fit the door with loose pin hinges, then take the door off and fix the frame hanging jamb only, the pop the door on and adjust before fixing it all solid. I like to use three hinges on outside doors, so I would probably recess my hinges in the hanging jambs first before assembly, but then fix the frames and doors separately, purely because I am comfortable doing it that way. I always use screws for my frame fixings, that way I can back them out easily and adjust things if it is not right first time. Also don't forget, paint the bottoms of the doors. French DoorsHere's a question from Alex, Hi Bill - great site and many thanks for your time in creating it. I was wondering if you had any tips on fitting French doors? My main question is when fitting, I am assuming that door frame is level with floor so nothing to trip on? Hi Alex, The reason it is uncommon to see timber framed doors any more, apart from cost, are the requirements of the BCA and local building codes, regarding fixing, glazing and water penetration certification. I built a high level deck a few years ago, and the access was to be via French doors. The doors were made by a local joiner who did a beautiful job. Solid Jarrah with adjustable timber louvres that are rarely seen these days. I had a heck of a job getting them certified. The water penetration side of it has meant that the rebates in the frame's sill have gone deeper than they used to be.

So, building from scratch, knowing the size of your frame, you can still get the sill just about level with the internal floor finish. If it is a concrete slab a recess is left in the concrete. As in the photo on the right. I have recently replaced two sliding doors in my place. The original door sills were 5mm or so above floor finish. The new ones are 20mm. I could have chipped the concrete, but as there already is a 120 step between the inside floor and verandah floor levels, I didn't see it as a problem. If I had to replace my old timber French doors in my old house that had a timber floor, I would do the same, that is let the new frame sit on top of the floor joists and just get used to the slightly higher sill. I definitely would not chop notches in the floor joists to let the frame sit lower, unless I could beef them up in some way to replace the lost strength. back to topMaking and fixing Heavy DoorsHere's a question from Rob. I will be making some doors for my shed. timber Frame sandwiched between ply or OSB sheets (to stop sagging) and hardwood T and G planks (siding) on the exterior. Very heavy.

About 1900mm high and 880mm wide each door. (two doors) ************************************** Hi Rob, I have made and fixed similar sized doors out of two layers of 16mm MDF with a 1.2mm lead sheet in the middle for radiology rooms. These were very heavy. From memory I used same sized jambs screws and hinges to swing them. Only I used ball bearing hinges to handle the extra weight. (This type of hinge is used on aluminium and glass doors on shops etc. also very heavy). I wouldn't use less than 32 thick timber for a door jamb. It is a hassle fixing and keeping straight ex 25 timber. I'd probably use ex 75 x 35 ( 3 x 1 1/2) internal frames for the doors. 4 x 2 seems a bit overkill, but I don't know how heavy you external boards are going to be. The strength of the doors will depend on your fixing of the ply or OSB to the frame. ******************************************* Hi Bill, thanks for the info. The 4x2 internal frame members are just "4x2" spruce used for house construction. Actually they are 38mmx89mm. They are cheap. I'd say that by the time I planed off a bit to straighten them out they would end up at around about 75x35 as you suggested. I can check through the timber in the store and get the straightest ones but they nearly always have something that will need to done so they can be used for a frame. ****************************************************** Hi Rob, If you went to the trouble of making lap joints, I'd be tempted to put a couple of braces inside the frame and just sheet the inside with ply and fix you boards directly to the frame on the outside. Save a sheet of ply. You mentioned mortise and tenon, if you wanted to make the job a definite project, you could make yourself a pair of frame and filled doors. I would fix the jambs with a pair of screws in four spots, just over your top hinge, just under the bottom and two more sets equally spaced in between. Architraves or Trim around windows and doors.As I said before, we don't do a lot of these now. They are not needed for steel door frames, and in a house or extension that is using steel frames, you can bet that the windows will have plastered reveals, either plasterboard or solid plaster.Not found it yet? Try this FAST SITE SEARCH or the whole web |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship |

||||||||||||||||||

|

|

|||||||||||||||||||

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||||||||||||